Dereck Mungoriwo

Culinary Operations & Restaurant Systems Specialist

I am a culinary operations specialist focused on improving kitchen performance through structured systems, process optimization, and data-informed decision-making.

With a foundation in professional culinary practice and analytical training, I translate real kitchen workflows into measurable operational models that enhance efficiency, control food costs, improve consistency, and support smarter management decisions.

Operational Methodology

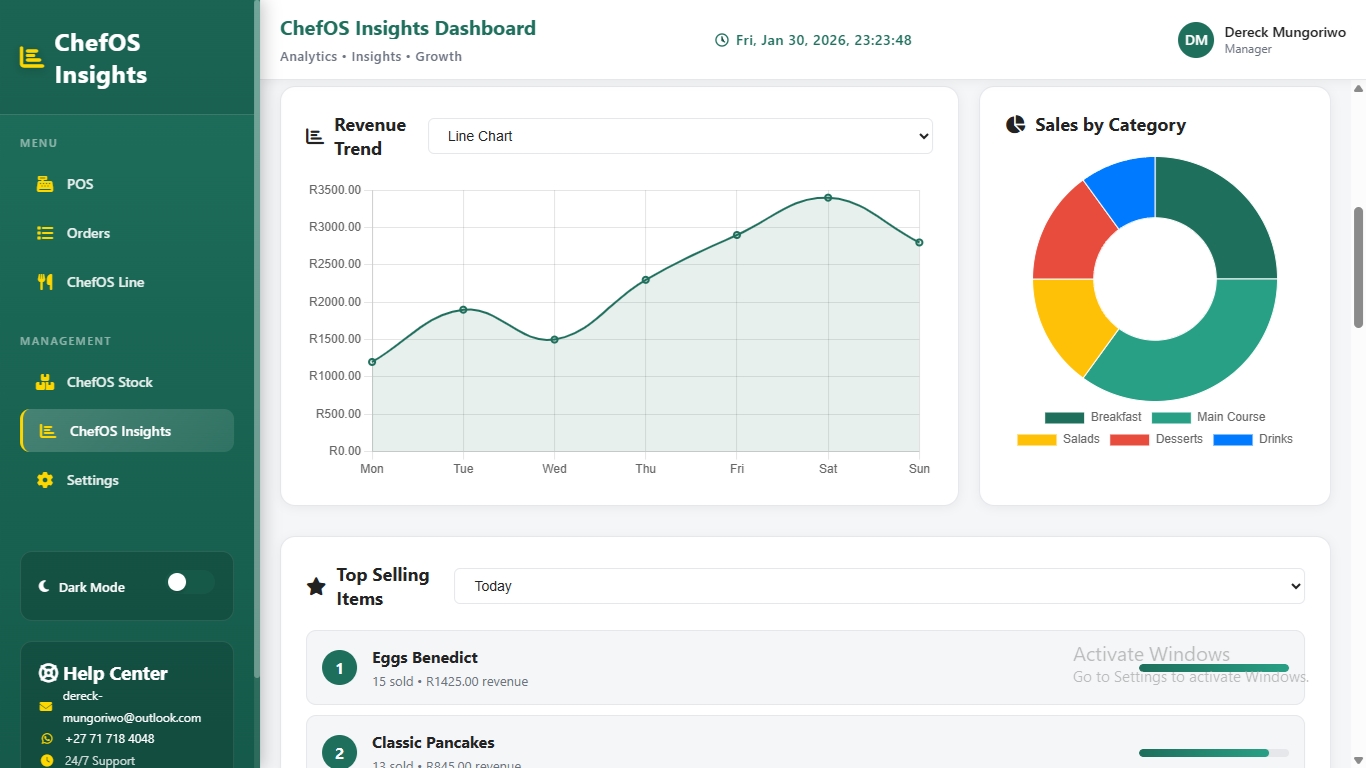

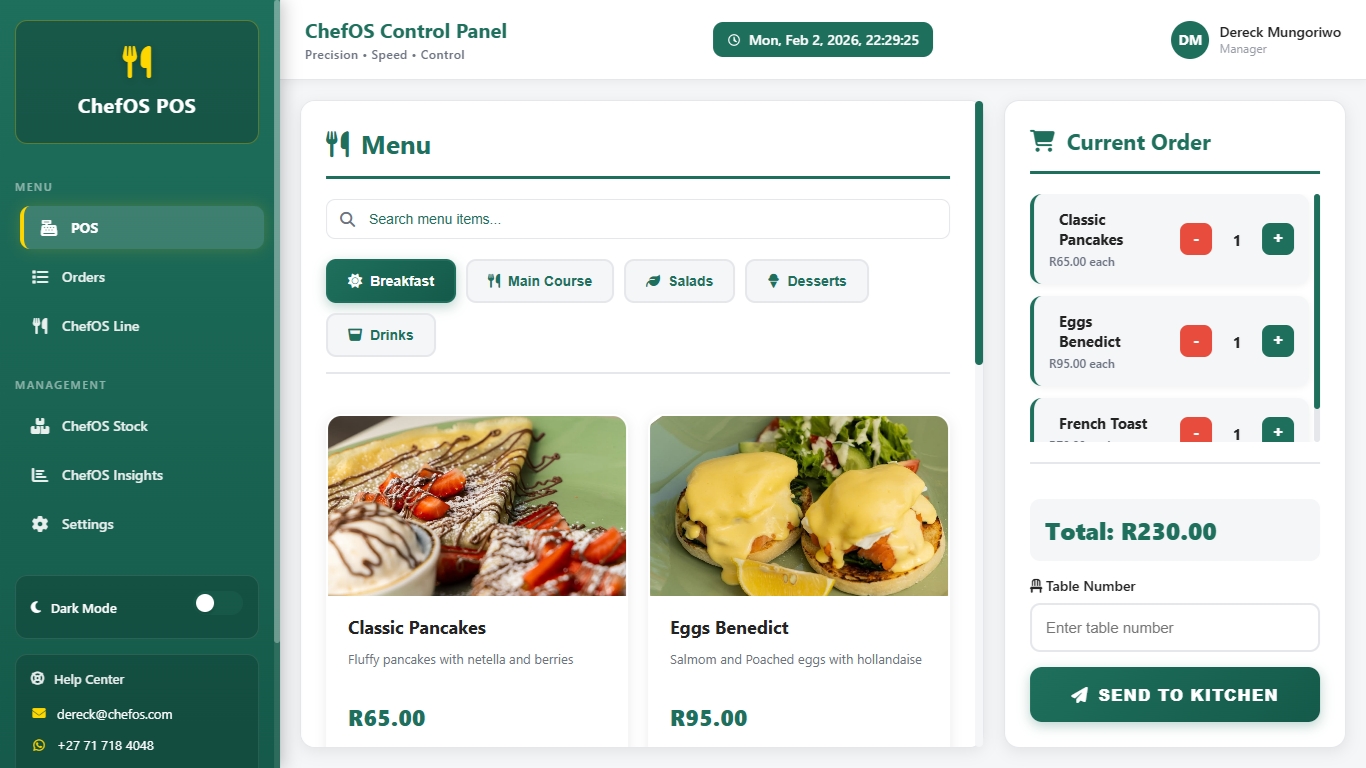

My approach to kitchen operations is structured around three principles: process precision, workflow efficiency, and data-informed decision-making. Culinary environments perform best when systems, timing, and measurable feedback loops work together to support consistency and control.

Operational Capabilities

- Process Standardization: Structured preparation methods ensuring consistency across service

- Production Flow Optimization: Station coordination and timing control for consistent results

- Cost Control & Yield Awareness: Root-to-stem, nose-to-tail ingredient utilization strategies to minimize waste and protect margins

- Quality Control Systems: Maintaining output standards through repeatable procedures

Operational Impact

Applying structured workflow systems and performance tracking to maintain consistency at scale, improve cost control, and support data-driven operational decisions.

Signature Dish: Precision & Presentation

Pan-Seared beef fillet with Roasted Vegetables, Chimichurri & Thyme Reduction

This dish exemplifies the intersection of culinary technique and operational precision—controlled searing for optimal crust development, precise timing for medium-rare doneness, and plating consistency that reflects systematic kitchen workflow.

Each component represents repeatable process execution: standardized protein portioning, coordinated station timing, and controlled sauce reduction for consistent flavor profiles across service.